Ball Mill Procedures

Ball Mill Inspection Sheet Form Procedures

Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. Ball Mill Inspection Sheet Form Procedures. 2 Apr 2014 The FL ball mill is a reliable choice for grinding cement clinker, gypsum and similar ...

BAll Mill Installation

Installation of a 23,000 pound Ball Mill in the Carissa Mine at South Pass City State Historic Site

ball mill installation procedures

ball mill installation procedures. Ball MillsMineral Processing Metallurgy. 2017 2 13 In all ore dressing and milling Operations including flotation cyanidation gravity concentration and amalgamation the Working Principle is to crush and grind often with rob mill ball mills the ore in order to liberate the minerals In the chemical .

Ball Milling

A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . Types of Ball Mills Drum ball mills Jetmills Beadmills Horizontal rotary ball mills Vibration ball mills Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material: hard ...

Variables in Ball Mill Operation | Paul O. Abbe®

Ball mill operation is often regarded as something of a mystery for several reasons. Ball milling is not an art it's just physics. The first problem will ball mills is that we cannot see what is occurring in the mill. The other problem is that many of the independent variables are nonlinear or have paradoxical effects on the end results. In ball milling of dry solids the main independent ...

Ball mill maintenance procedures

Ball mill maintenance procedures Oct 12, 2017. 1, ball mill operation and maintenance personnel to be familiar with the structure of the equipment and the performance of the components of the name, specifiions, role. 2, the operator according to the "four" principle, to lubrie the drawings marked by the Ministry of lubriion ...

Quick and Easy Black Powder Ball Mill — Skylighter, Inc.

· A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls,flint pebbles ...

Grinding Procedure Ball

Large Ball Mill Procedure For Installation How is the ball mill applied to mineral grinding composed Large double frame ball mill installation Read More pdf large mill installation 99 customer review Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials Large to mediumsized ball mills are the cost. Get Price . Standard Operating Procedure For Ball Mill ...

ball mill manufacturing procedures

Ball Mill RETSCH powerful grinding and homogenizationRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in ...

Ball Mill Inspection Sheet Form Procedures

Ball Mill Inspection Sheet Form Procedures. 2 Apr 2014 The FL ball mill is a reliable choice for grinding cement clinker, gypsum and similar materials of moderate ... The ball mill is key equipment in grinding industry, especially in mineral ore dressing plants. It is .

procedures for operating ball mill

operating procedures ball mill Standard operating procedure for ball mill standard operating procedure for the grinding and extraction of lead in paint using nitric ac ball mill a ball mill is a type of grinder used to grind and blend materials for use in mineral info standard operating procedure sop · BALL MILL STANDARD OPERATING ...

Procedure For Ball Mill

Operating procedure for ball miller,operating procedure for ball miller note: internal timer has been modified to time for 9,999 minutes extended time. this ball mill was designed to run minutes, average time. the original total time was minutes maximum. now it is 9,999 minutes 160 hours. To operate longer times, two cooling fans have been installed and an

Ball Mill: Operating principles, components, Uses ...

· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size. The large balls tend to break down the coarse ...

Procedures for Systematic Start up and Stoppage of Ball Mill

· Ball mill start up procedure: The systematic start up procedures for Ball mill are briefly outlined here underCheck the readiness of upstream and down stream equipment in the process circuit, Inform the turbine house of Cogeneration plant to ensure the stable operation of TurboGenerators (TGs) and connected boilers. During steam pressure fluctuations in boilers, the ball mill should not be ...

Procedures Of Ball Mill

Ball mill manufacturing procedures ball mill manufacturing procedures. theory and practice for us stoneware. one that uses steel balls as grinding media, while a pebble mill is one that uses flint pebbles fundamentally, milling is a process for reducing the particle size of solids production mills for either wet or dry size reduction.

Procedures For Operating Ball Mill

procedures of ball mill operating procedures ball mill Boiler Type ZOZEN boiler covers an area of 150 thousand square meters, with an annual production capacity of 2000 industrial boilers and 25000 tons of products have been sold to more than 100 countries and regions and set up offices in many countries to ensure that they serve customers at the first ...

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

(DOC) BALL MILL STANDARD OPERATING PROCEDURE: SL .

BALL MILL STANDARD OPERATING PROCEDURE: SL PROCEDURES STATUS REMARK NO 1. Ensure that all the items mentioned in the prerequisites are available 2. Connect the power supply (3 Phase) [415 V, 50/ 60 HZ] with Earthing. (use 5 core cable to draw earthing from the input supply). 3. Coupling alignment with respect to gear box and rubber bush ...

ball mill erection procedures

Ball mill erection manual Manufacturer Of Highend. Ball mill erection procedures qlifebe ball mill erection manual book ball mill erection manual book TPH Cobble Crushing Plant Vietnam is an important mining export country in Asia, especially the exportation of Contact Supplier Oline Chat. ball mill erection procedure theflyingfishtheatrede

ball mill manufacturing procedures

ball mill manufacturing procedures ball mill manufacturing procedures. Theory and Practice for US Stoneware. one that uses steel balls as grinding media, while a pebble mill is one that uses flint pebbles Fundamentally, milling is a process for reducing the particle size of solids production mills for either wet or dry size reduction.

Ball Mill at Thomas Scientific

.GUI The PM 100 planetary ball mill is a benchtop unit designed to pulverize soft, fibrous and brittle materials. The mill develops extremely high centrifugal forces resulting in energy input that is up to 50% higher than in other planetary ball mills. It has a single grinding station for.

Latest Posts

- كسارة موثوقة

- بيع تأثير محطم ملموسة

- اندونيسيا الجبس المجلس آلات المصنع

- الحجر الرملي الاصطناعي الأسعار في نيجيريا

- إعادة تدوير المعدات الميكانيكية المصنعة

- كينيا كوارتز محطم الصانع

- معدات التعدين وتجهيز خام الكروم في ألمانيا

- مطحنة الكرة قدم قدم طويلة

- خطط لبناء كسارة الفك في تونس

- التقطيع آلة طحن

- مطحنة عمودية فاصل الاسمنت

- الدنمارك معدات التعدين المصنعة

- مطحنة الكرة لسحق الفلسبار المعدنية في نيجيريا

- كيفية ضبط تأثير محطم منفذ قوات الدفاع الشعبي

- Milling 26amp 3b Grinding Process

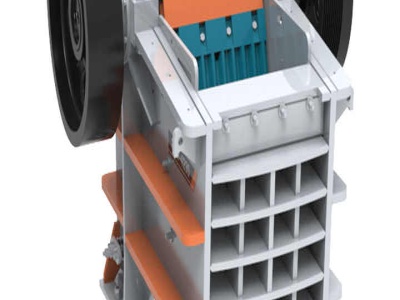

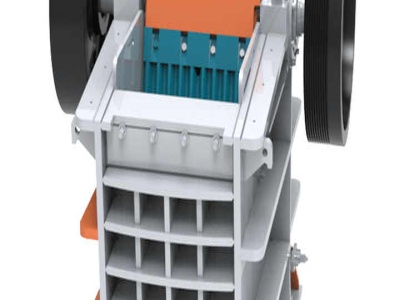

- Jaw Crusher Technical Requirements

- Micro Pharmaceutical Powder Pulverizer For Sale

- Gold Tailings Mining Equpment China Feb

- Penggilingan Emas Penggalian

- Broons Kirpy Rock Crusher

- Copper Ore Processing Plant For Sale In Pakistan

- Jaw Crusher Illustration

- What Is Iron Ore Not Used In

- Sale Basalt Stone Crusher For Sale

- Deep Groove Ball Bearings For Machine 6814

- Portable Surface Grinding Machine

- Coal Mining Drill Suppliers And Coal Mining Drill

- Finland Crushers Trillion

- Produsen Indonesia Proppantnya

- Green Island Jaw Crusher