To Increase Production In Cement Grinding

MAINTENANCE IN THE CEMENT INDUSTRY

Maintenance in the cement industry is one of the contributors to the production cost and represent typical 15 – 25 percent of total manufacturing expenditure. Many companies have tried to use standard production methods to control maintenance costs.

Raw Material DryingGrinding

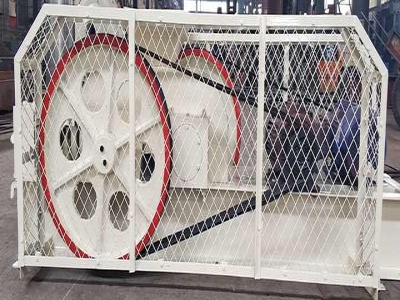

Roll presses are also used in, particularly in upgrading existing ball mill circuits as pregrinders to increase production or to reduce specific power consumption in grinding operation. Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (/sec above the ball charge), can ...

CEMEX Strengthens Guatemala Presence – Cement Americas

Oct 06, 2021 · Current grinding capacity at the plant is about 500,000 metric tons of cement per year. Following the completion of the project, production will increase to 900,000 mtpy. It will rely on modern and efficient processes for cement production and environmental standards. The new grinding mill, which will produce lowcarbon cements, will be ...

Carib Cement to spend b to increase cement production ...

Aug 09, 2021 · Carib Cement to spend b to increase cement production in 2022 ... ''The expansion will introduce novel grinding additives to the manufacturing process and further enhance the production .

To Increase Production In Cement Grinding

Grinding aids work mainly by dispersing ground cement particles to avoid agglomerates, Increase mill efficiency .enabling an increase in production of up to 10 20 per cent. also some material can increase the 28days strength 10 17 and reduce the cost .The prime factor behind the usage of cement grinding aids is the elimination of the coating effect of clinker on grinding mill walls and to ...

(PDF) Impacts of Cement Industry on Environment

It is estimated that about 900 kg of carbon dioxide (CO 2 ) gas is emitted into the environment for every ton of cement production (Benhelal et al., 2013), and the cement industry is accounted for ...

Cement Particle Size Analysis

About half of the production cost in the cement industry is energy consumption – primarily during burning and grinding. Prompt and precise control of cement grinding and material testing not only avoids energy and cost intensive overgrinding, it also allows cement grade changes in a very short time within one plant with only small amounts of outofspec material.

to increase production in cement grinding

Kenya's Bamburi Cement says to increase grinding capacity . Kenya's Bamburi said it plans to increase its cement grinding capacity by 900,000 tonnes at one of its two plants by mid 2018 and lift total annual production capacity to million tonnes.

How To Increase Cement Mill Capacity

Grinding cement industry news from global cimpor intends to increase its cement production capacity in mozambique to after a new grinding unit is put on stream, the company has said in a new unit at the plant in dondo, in southern mozambique, has a production capacity of 60thr.

Effect of specific energy consumption on fineness of ...

· Grinding aids are organic compounds added during the grinding of clinker to prevent cement particle attraction and reagglomeration, thus resulting in clinker and energy savings which can both lead to reduced CO 2 emissions. This paper seeks to quantify the increase in grinding mill outputs derived from the use of amine or glycolbased GA.

To Increase Production In Cement Grinding

To Increase Production In Cement Grinding. Aug 30 2012 cement manufacturing process phases production of cement completes after passing of raw materials from the following six phases these are raw material extraction quarry grinding proportioning and blending preheater phase kiln phase cooling and final grinding Chat Online. Contact Us [email protected] Zhengzhou high tech Industrial ...

Reducing energy consumption of a raw mill in cement industry

· However at the same time the production of cement increased from 570 million tons to billion tons per year. As a result, about 5% of global carbon dioxide emissions originate from cement production. About half of this is due to calcinations and the remaining half is due to combustion processes. In a cement plant, using energy efficiently during grinding process will lower the .

to increase production in cement grinding

Bamburi Cement to increase grinding capacity by 40 . Kenya's Bamburi said it plans to increase its cement grinding capacity by 900,000 tonnes at one of its two plants by mid2018 and lift total annual production capacity to million tonnes. The ...

Reduce Energy Consumption: Cement Production

Aug 25, 2011 · Drives also are used to power roller mills for grinding different blaine of slag for cement, and for starting and running multiple roller mills, ball mills, and overland conveyors. A Chinabased cement plant used VFDs to significantly reduce its energy consumption in its dryprocess kilns, responsible for production of million tons of ...

to increase production in cement grinding

Grinding mill Cement industry news from Global Cement. Apr 28, 2017 25 May 2016. India: Ambuja Cement has completed a /yr capacity upgrade at its Sankrail grinding plant in West Bengal. The US50m upgrade was commissioned on 24 May 2016. The cement grinding plant has increased its production capacity to /yr from /yr. The upgrade was originally announced in late 2012. .

to increase production in cement grinding

CNC Grinding aid for cement Google Patents. Properties and Uses: The use of HS CAG allows the cement producer to increase cement production .

to increase production in cement grinding

Grinding aids for high performance cements CADD Mapei. increase production and fineness, or performance enhancers with effect on cement hydration), the choice of the most appropriate relies on a detailed investigation that should consider all the characteristics of the cement. Grinding aids for high performance cements Grinding aids are organic compounds that are added to the mill during ...

O Increase Production In Cement Grinding

To increase production in cement grinding mining crusher petcoke grinding for clinker production the coal mill are being supplied to cope with the increase in chat get price increase the production from grinding plants to increase production in cement grinding contact form figure 2 the integrated cement plants and standalone cement. Optimization Of Cement Grinding Operation In Ball Mills . Jul ...

To Increase Production In Cement Grinding

Suhar cement to add new grinding capacity cement is expected to start its new cement grinding operation later this new facility, featuring a cement mill with a capacity of around has been planned to increase the local production of cement by setting two new gray cement plants, a white cement plant and two cement grinding facilities.

The Effect on the Performance of Cement Grinding Aid ...

particles, reduce grinding energy, and increasing production, Cement grinding aid is widely used in cement industry[14]. 29 Journal of Materials, Processing and Design (2017) Vol. 1, Number 1 Clausius Scientific Press, Canada. Below chemical regent are normally used as cement grinding aid: three isopropanolamine, ethylene glycol, triethanolamine, sorbitol, diethylene glycol, glycerin, etc ...

Latest Posts

- طحن المواد flowable مع الحجر

- السكك الحديدية سحق النبات التكلفة

- استهلاك الطاقة من كسر الصخور النارية

- ريمون ميلز الأمريكية

- معدات التعدين كسارات الفحم للبيع في نيجيريا

- أستراليا معدات سحق الكلي

- مصنع كروشار

- مطحنة الأسمنت الكرة

- خلع الملابس خام كسارة الفك

- كسارة الفك القديم يستخدم فقط في جيم الملح

- إزالة الكبريت من كربونات الكالسيوم الخبث

- سفينة التعدين سحق الأنابيب

- سحق خام الحديد الكثافة

- التأثير الكلي الفرز

- العلامة التجارية الجديدة المحجر سحق سعر المصنع

- Design Theory Roller Grinder Mill Crusher

- Sandstone Saws Sandstone Saws Manufacturers For Sale

- Moinho Limestonestone Linha De Produo De Plantas

- Dry Magnetic Separator Australia Brand In South Africa

- Salt Plant Equipment Experts

- Buy Liquid Mercury South Africa

- Coal Pulverizer Stone Crusher

- Mauritania Coal Sector Issues

- Introduction Of Grinding Swarf Recycling

- Milling Machine Mf

- Micro Air Angle Die Grinder

- Pengertian Mesin Grinding Sekurang

- Design Of Cement Plant Structures

- Sbm Silica Sand Crusher

- Crusher Dust Mines South Africa